Parts & Specifications

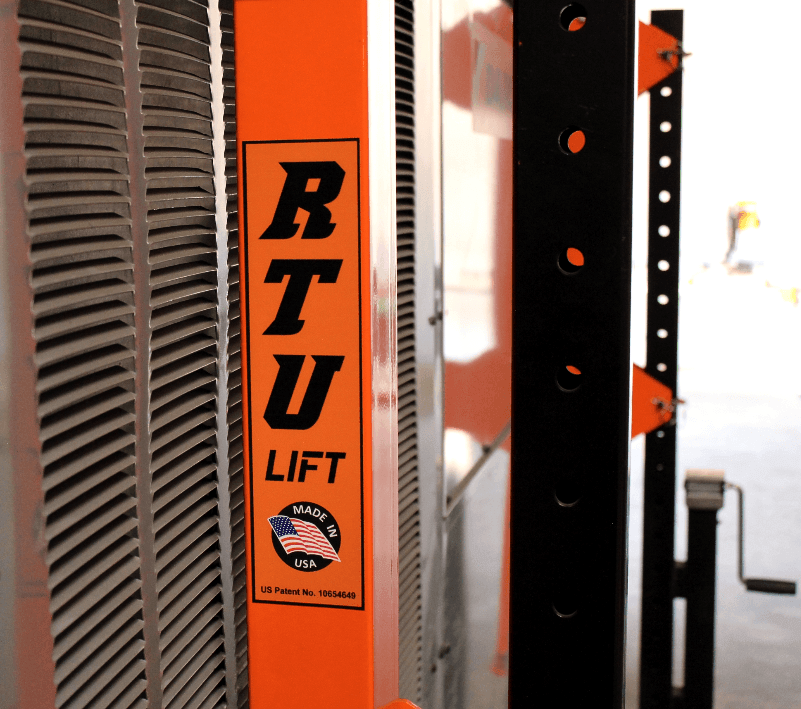

Take a look at some of the key components on the RTU Lift.

-

Tool Bag w/ Tools Included

ButtonTool Bag includes:

- (1) Telescopic Magnetic Pickup Tool

- (8) Self Tapping Screws

- (1) 1/2" Titanium Drill bit

- (1) 3/4" x 1/2" Socket Adaptor

- (1) 3/4" Socket

- (1) 1-3/4 " Hole Saw

- (1) Reach Nut Tool

-

Fixed Wheels (2-Pair Chocks Included)

Button

- 8.5" x 18.5" Wheel/Tire

- Roller Bearings

- Rated for 950 Lbs.

-

(1) 1/2" Nut and Bolt

Button- Modular / Serviceable

- Remove (1) 1/2" Nut and Bolt to remove the wheel from the upright

-

Dual Swivel Caster

Button- Aircraft Grade

- Roller Bearings

- Rated for 950 Lbs.

- Remove (1) 1/2" Nut and Bolt to remove the wheel from the upright

- Four-hole caster plate is zinc plated

-

Subframe Bracket

Button- Only (2) 2-1/2" bolts to mount each bracket

- Self locking hardware

- Safe lifting points

-

Extra Subframe Bracket Kit w/ Hardware

Click Here to view video- The extra Subframe Bracket kit is essential when moving rooftop units over gas piping/obstacles on the roof. Click below to see video.

- This kit is very helpful when moving multiple rooftop units at a time.

- (4) Extra Subframe Brackets

- (8) 1/2" x 1-1/4" Flanged Bolts

- (8) 1/2" Flanged Nuts

- (8) 5/16" Self Tapping Screws

- (8) 1/2" Double Tapped - Zinc Plated Reach Nuts

- (1) Extra Reach Nut Tool

-

Specification and Safety Label

Button- 2500 Lb. Lift Capacity

- 50 Psi max air pressure on fixed wheels

- 75-100 Psi max air pressure on swivel wheels ( See TIre Specs)

- All hardware: 1/2" x 13tpi Grade 5 or better

-

Subframe Bracket Bolted

Button- Our (4) brackets are bolted to the rail of the rooftop unit creating safe and secure lifting points

-

Sleeve

Button- Post assemblies designed to acocommodate up to 5" offset curb adapters.

-

Rubber Pads

Button- Magnetic

- Easily adjustable for all RTU's

- Protects the cabinet when in compression

- Stainless Steel Construction

- 1/2" Rubber / 40 Durometer

-

1/2" Quick Release T-Handle Pins

Button- Line up holes on upright and insert T-handle pins

- Attach safety clip pin w/ lanyard

-

Manual Lifting Jack

Button- 3000 Lb. Rated Lifting Jack

- Accessible grease fitting

- Simple manual operation

- No messy chainfalls

- No electrical/battery components to maintain/fail

-

Stable & Safe

Button- 4 Points of contact

- No rocking or swaying when in use

-

USA Made and Assembled

Button- The RTU-2500 Lift System is made and assembled in the USA.

- Commercial Grade Materials

-

RTU-2500 Lift Systems In Stock

Button- We keep the RTU-2500 Lift System in stock for immediate delivery

Storage System

- Easily manuevered and transported with a forkift or pallet jack

- Disigned for forklift access from all 4 sides

Small Footprint

- Small footprint (38" x 78")

- Fits in any standard pick up bed

Shipping and Storage System

- The RTU-2500 Lift System is secured with 3" threaded thumb knobs

- Easily store and remove the RTU-2500 from storage system

- Small footprint (38" x 78")

- Wood components are assembled with adhesive and screws

- All edges are sanded and rounded to prevent splintering